Magnetic annealing eliminates the work hardening associated with the machining of parts or the deformation of the material (-> reduction in hardness) and modifies the structure to give the optimum magnetic characteristics.

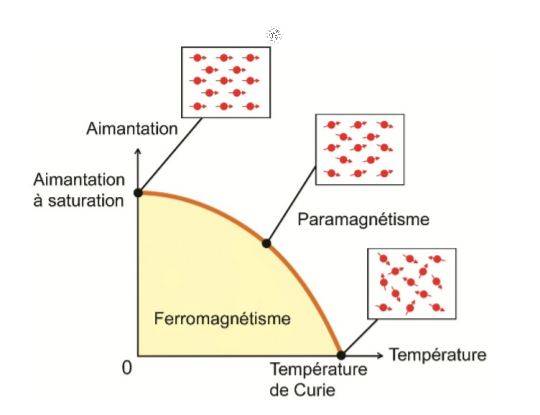

It is carried out under vacuum; the holding temperature is above the Curie point of the material. This type of annealing is mainly carried out on soft ferro magnetics (pure iron, ferritic, martensitic stainless steels). The parts will serve as field amplifiers (magnetic cores) and or field channelizers (magnetic shielding).

This treatment is dedicated to high-tech industries: connectors, aeronautics, industrial looms,…