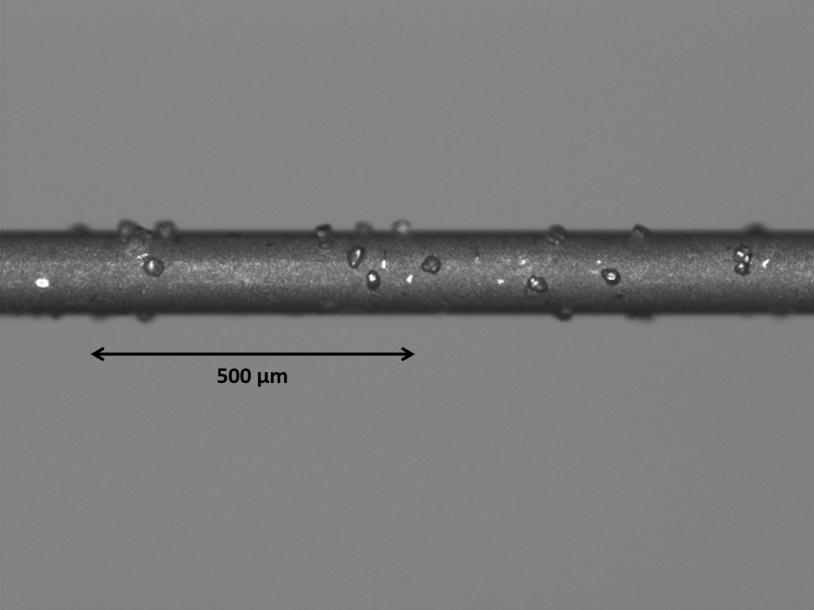

We manufacture and provide a portfolio of diamond wires from 60 µm to 400 µm in diameter.

MAIN BENEFITS of our diamons wires are:

- REDUCED COST OF OWNERSHIP

Faster cut times:

6 - 8 x faster than slurry, application dependent

Increased capacity with lower capital expenditures

Faster ROI to justify initial capital investment

Roadmap to lower wafer cost and higher throughput:

Lower cost resulting from reduced TCO

Less expensive secondary process costs

Re-use of wire / Reduced utilities

Less plant complexity:

Reduced running costs such as electricity and cooling water

Bundled consumables for optimized processing

- HIGHER THROUGHPUT :

Flatter wafers - Roadmap for thinner wafers / Holistic approach to cutting /Improved wafer topology / Excellent cutting accuracy

- MAINTENANCE & ENVIRONMENT FRIENDLY:

Fewer wire spool changes / Cleaner and faster process / Ability to use water-based cutting fluids

- SEAMLESS INTEGRATION INTO EXISTING WAFERLINE SYSTEMS

We offer a COMPLETE TECHNICAL and LONG TERM SUPPORT FOR the COMPETITIVE NEEDS of our customers, including personalized recommendations.

Our diamond wires are tailor made for specifications and/or technical requirements of our clients, and dedicated to their needs :

PRINTABLE TECHNICAL DOCUMENTS: Diamond wires portfolio technical data

|

|

| |

| |

|